|

|

|

The Norton Mine Slideshow The Norton Mine Slideshow--part two Energy Storage Applied Research Program |

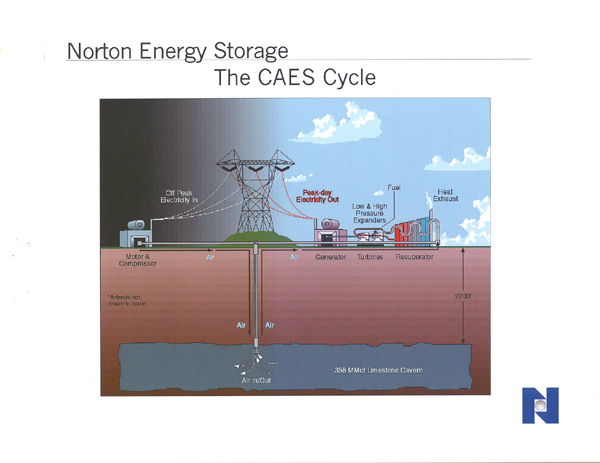

Norton CAES FacilityA Compressed-Air Energy Storage (CAES) facility consists of an energy-production and an energy storage system. The Norton CAES energy-production facilities operate by using off-peak electricity available at night and on weekends to compress air into the storage vessel (Norton Mine). During intermediate- and peak-demand periods, compressed air is released from the pressured energy-storage system, heated by combustion of natural gas, and used to drive high efficiency turbines to produce electricity. Using electric powered compressors injecting the air through dedicated wells charges the storage vessel. Air free flows from the mine to the energy production system A CAES facility consists of an energy-production and an energy storage system. The Norton CAES power plant facilities will operate by using off-peak electricity available at night and weekends to compress air into the Norton Mine. During week daytime intermediate and peak-demand periods, compressed air will be released from the pressured energy-storage system(mine), heated by combustion of natural gas, and espanded through the energy-production system.

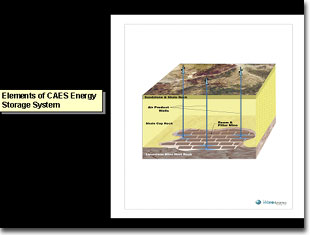

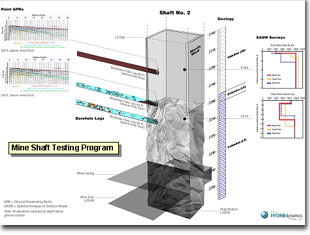

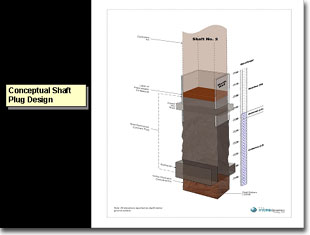

Norton Energy Storage SystemKey elements of the energy storage system are the air storage vessel (mine) and air injection and production wells. The Norton Mine will be developed for air storage by constructing conventional gas-type wells into the mine for air injection and withdrawal. The mine is currently open to the atmosphere only through two existing mine access shafts. The mineshafts will be sealed with impermeable plug materials. The Hydrodynamics Group. LLC and Sandia National Laboratories completed field and laboratory studies to confirm the integrity of the Norton Mine as an air storage vessel. The focus of these studies was to confirm that the mine would hold air at required storage pressures. The results of these studies show that it is feasible to develop the Norton Mine for use as an air storage vessel for CAES. The limestone, in general, is massive and homogenous with very few discontinuities that would significantly affect air storage performance. Modeled estimates of mine stability under dynamic pressure loads indicate the integrity of the mine will not be compromised. The pressurized air may relieve some of the stress on the mine walls and roof, but stress relief will be within the elastic properties of the limestone.  |

|

|

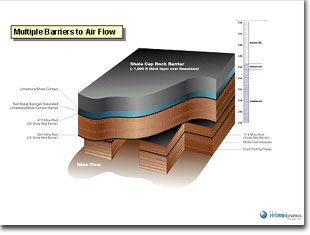

The limestone and shale caprock have an extremely low permeability to air. Air migration through the mine host rock is predicted to be extremely low, based on the homogeneity of the limestone and shale, and on the results of air permeability testing. The effective permeability in the salt water and kerogen-saturated caprock materials is extremely low. The quantity of air that will migrate into the pore space of the mine host rock as cushion gas was modeled to be approximately 4 percent of the total volume of air initially injected into the mine in 10 years. Approach to Norton Mine Performance Analysis

The design and operation of a mine air storage system is first based on the concept of multiple barriers to airflow, and second on reservoir engineering hydraulic principles. An additional consideration is that air pressures will not compromise the integrity of the mine by creating potential pathways (fractures) for air migration, and/or the loss of storage space due to collapse. Thus, the goals of these studies were to confirm the integrity of the Norton Mine at anticipated air storage pressures, and determine the potential for air migration from the mine.

The Hydrodynamics Group, LLC and Sandia National Laboratory field and laboratory studies characterized the Norton Mine as a storage vessel. These characterization studies included an assessment of existing geologic, hydrologic, and rock physics data. Based on this testing data and state-of-the-art analysis methods, the underground facility performance as a CAES facility was characterized. Specifically, the mechanical and flow response of the mine (including an envelope of rock mass surrounding the mine) was modeled in a way to simulate CAES operations. This facilitated predictions of air migration into the host rock, and rock movement during the CAES facility operational lifetime.

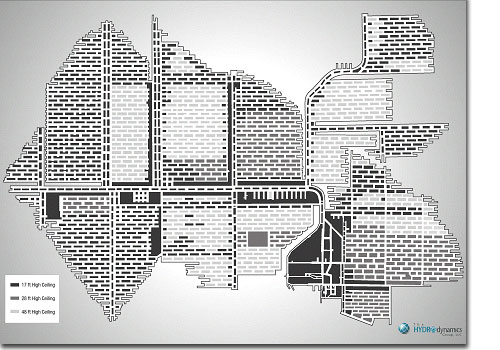

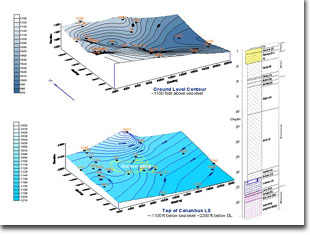

Norton Mine Air Storage VesselThe Norton Mine operations began in the early 1940's as a raw material source of high-grade calcium carbonate (calcite) ore used by Pittsburgh Plate Glass Company (PPG) for the production of synthetic soda ash. The rock was later used for cement production. Mining operations ceased in 1976. PPG maintained access to the mine from 1976 to 1999. Norton Energy Storage, LLC currently maintains access to the mine. The Norton Mine was developed by the systematic removal of about 338 million cubic feet of limestone at a depth of about 2200 feet below the surface. The mine covers an area of about 7,000 feet by 4,000 feet (7,763 acres). At present, access into the mine is through one of the two mineshafts. Both shafts were constructed in 1942. Both shafts are 16 feet by 7 feet clear opening (inside steel sets), and are concrete lined from the collar to approximately 70 feet above mine floor with the exceptions of sections left open for entrapment of surface water at the 300 foot depth in both shafts. The shafts are 550 feet apart. The depth of Shaft #1 is 2,323 feet below ground surface. The depth of Shaft #2 is 2,258 feet below ground surface. The floor of the mine in the area of the shafts is about 2,249 feet below ground surface. The mine was developed laterally from the shaft areas using a system of rooms and pillars. Specially, the mine was constructed using long panels, with cross-link passageways to connect panels. The link passages served mostly as communication corridors (e.g. ventilation), with a back height of about 20 to 25 feet. The gross mine geometry has a North-South and East-West hallway grid pattern. Initially, the rooms and entries were on 80-foot centers, with entry dimensions of 28 feet wide by 25 feet high. Subsequently, the entry and room configurations were on 75-foot centers with both room and entry widths of 32 feet. The three panel room heights of 17-, 28-, and 47- feet are control mined by splitting the limestone on 2 to 3-inch thick shale and oil shale bedding plains that are continuous over the area of the mine. Approximately 47 percent of panel rooms are 17-feet high, 21 percent are 28-feet high, and 32 percent are 47-feet high (Figure 2.2-1). This room and pillar mine configuration is remarkably stable, owing to a combination of careful application of drill and blast mining methods, 40-50% extraction ratio, and a very competent and relatively unfractured host rock mass. As a result, decreasing amounts of ground support were used as excavations progressed using the experience of stability. Most of the mine remains unsupported. Certain high traffic areas were roof-bolted for safety. No large rock falls have occurred in the mine since closure in 1976; the limited number of falls that were observed during the recent characterization were mining related (as per personal communications with mine personnel). The mine is within the Columbus Limestone, a single stratigraphic horizon dipping approximately 30 feet per mile to the southeast. The limestone and overlying shale extend over several counties surrounding the mine. The limestone is described as a gray to bluish gray, partly crystalline limestone bedded in various thicknesses, separated by 11 major partings of shale varying in thickness from trace to over one inch in thickness. There are 15 horizontal bands of cherty nodules within the mined interval, with the majority of these bands concentrated in the upper layers of stone. Chert is a generic name for micro-crystalline quartz, often containing micro-fibrous chalcedony with interstitial opal. Secondary permeability features, such as joints or fractures, are essentially absent in the limestone. The limestone extends to a depth of over 150 feet below the floor of the mine, based on exploratory bore-holes drilled by Acres America. The limestone mine roof is overlain by approximately 1,947 feet of Mississippian-age and Devonian-age shale (320- to 400 million years old rock), with minor interbedded sandstone, which is overlain by 213 feet of Pennsylvanian- and Mississippian-age sandstone, overlain by about 44 feet of glacial drift and till materials. The roof of the mine is from 5 feet to 35 feet below the shale caprock material, with an average depth of 15 feet. The mine is below the water table. The depth to the water table is on an average 24 feet below ground surface. Evidence of minor amounts of water was observed throughout the mine; however the mine is dry for the most part. Water seeps into the mine through the two mineshafts at the contact between the lower shale and upper sandstone bedrock materials at an approximate depth of 290 feet below ground surface. Water is collected in water collars in Shaft #2, and is either pumped to the surface or discharged into a sump below Shaft #1. Water was also observed to seep from 2-inch diameter pressure relief holes drilled vertically into the shale above the mine roof. Evidence of seepage is limited to stalactite salt crystals protruding from a small fraction of the numerous boreholes. Additional evidence of water in the mine included wet zones in the eastside (down-gradient section) of the mine and at one location in a northwest section of the mine, where minor pools of salt water have formed. Mine StabilityThe Norton Mine has been a stable structure under ambient atmospheric conditions for the past 57 years. Our geological engineering studies show the mine is stable as a pressure vessel. The stability of the Norton Mine as a pressurized air storage vessel is due to a number of factors, including the depositional history, rock composition, structural geology, earth-induced stresses in the rock, mine geometry, mine construction method, and hydraulic conditions. As previously noted, modeled estimates of mine stability under dynamic pressure loads further indicate the stability of the mine will not be compromised. The overall conclusion drawn from this study is that the Norton mine is uniquely well-suited to the requirements of a gas storage facility. Air migration rates seem to be extremely low, the gas front does not advance more than 60 ft. into the surrounding rock after 50 years of pressurization, and the system appears capable of supporting all six phases of the proposed operation plan. Specific conclusions drawn from the numerous mine performance modeling scenarios are:

|